Climate Coating Solutions

Contact us: info@climategcc.com

+966 55 271 0023/540376553

Tel/Fax- 012590034 –

Address: PO box- 516,New industrial area,

Jamum City – 21936

Kingdom of Saudi Arabia.

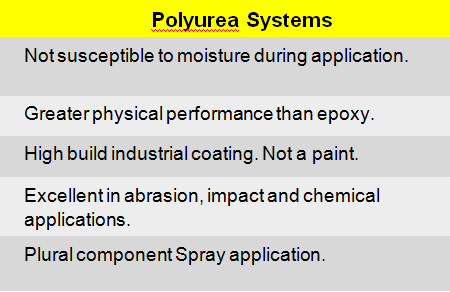

Purpose of this document

- Provide a brief explanation of Polyurea systems

- Provide difference of Polyureas over traditional epoxies

- Provide information on certain application/industry areas

- Provide benefits of our systems over traditional coatings systems

What is Polyurea?

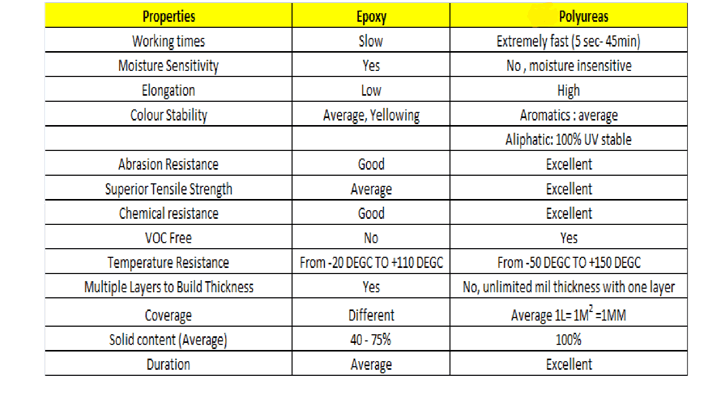

Polyureas are closely related to polyurethanes. Both are two component systems made with Isocyanate-based materials. However, while the second component in polyurethane is polyol resin, the second component in polyurea is a polyether amine.

In terms of performance, conventional polyurethanes require a catalyst, which is sensitive to temperatures and moisture. Low temperatures can slow the reaction and moisture can interfere with the reaction causing blistering and other negative effects. Polyureas, on the other hand do not require a catalyst. Reactivity for these coatings is fast, typically, 3-10 seconds. Consequently, they are able to cure at temperatures as low as -20 C and in the presence of moisture.

In terms of performance, unlike polyureas, epoxies require a catalyst. They are sensitive to temperature, humidity and moisture, giving them a narrow window for application. Unlike polyureas, epoxies have extensive cure time and little or no elongation properties. This leads to

frequent failure of the coating with expansion or movement of the substrate.

On the whole, Polyureas offer significant advantages over traditional Epoxy systems

Our new range of product offer significant advantages over traditional lining systems

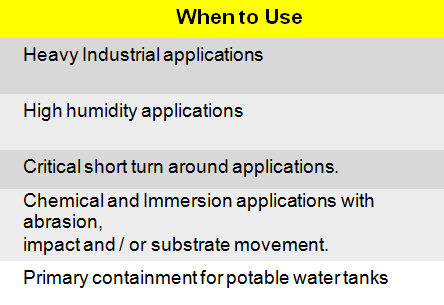

- Rapid spray applied application Seamless

- Excellent abrasion resistance, corrosion resistance,

- chemical resistance, impact resistance

- High tear strengths and elongation Capabilities

- Flexible when cured even at extreme temperatures.

- Excellent adhesion to most substrates

- Fast cure and reuse times, Reduces expensive shut down time.

- Can be built to any thickness in one application

- Contains no VOC’s or Solvents

- Large operating temperature range.

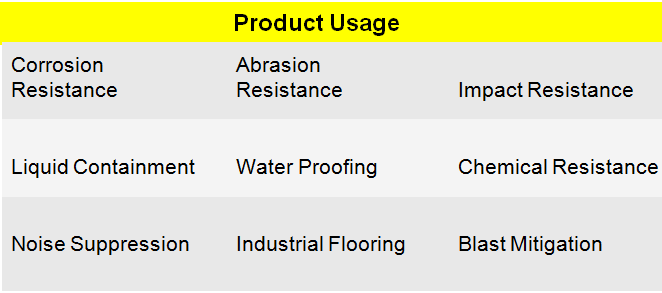

Our products offer solutions for a variety of lining and flooring requirements

Some of the primary areas of application include

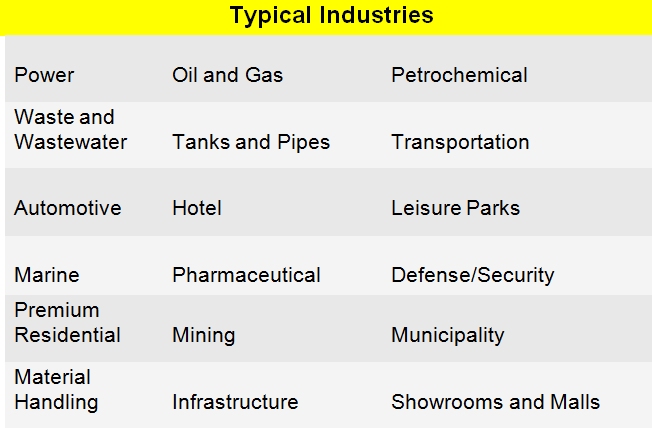

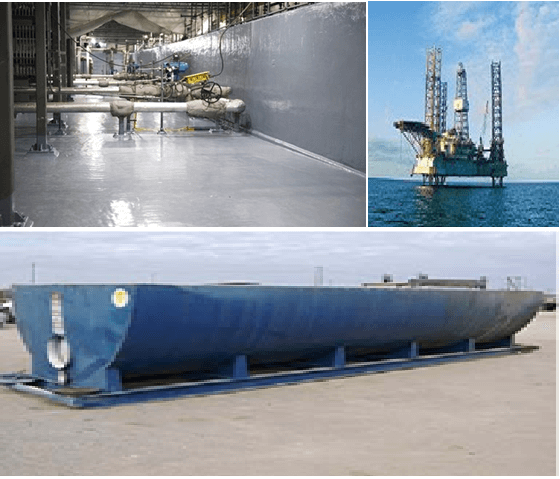

Petrochemical Industry

- Protects steel pipes & tanks from chemically corrosive environments

- Applicable during primary construction or re-development Superior elongation & tensile strength

- Usable for pipes with PU foam insulation Reduces maintenance services and costs

- Fast cure decreases return-to-service time

- Supports environmental stewardship, Refineries,

- tank interiors & exteriors, oil platforms, piplines, gas industries and Cooling towers etc.

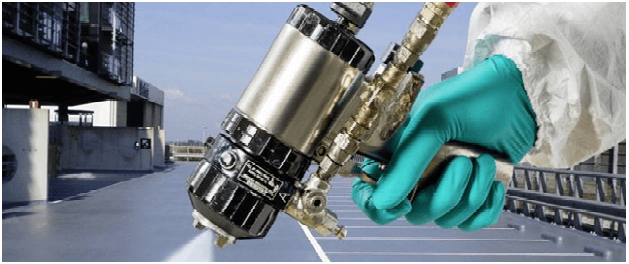

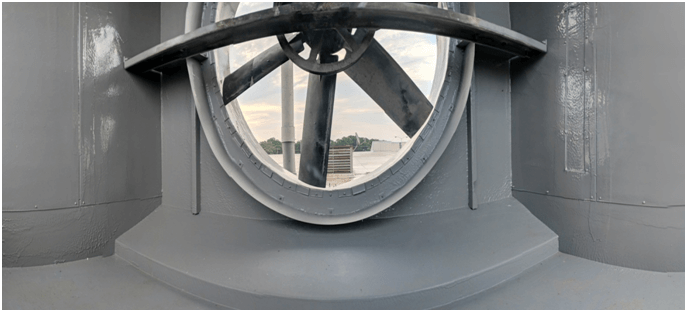

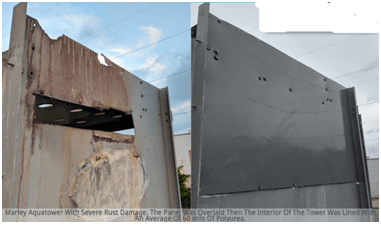

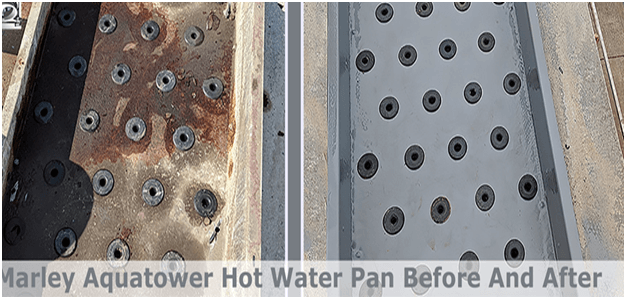

Polyurea coating of HVAC Cooling Towers

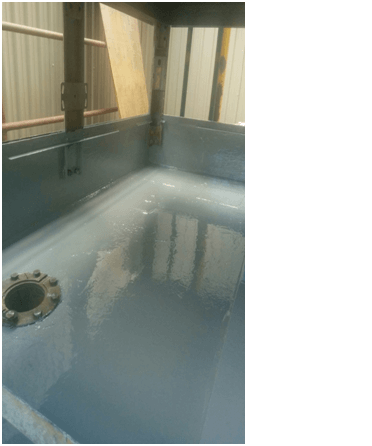

Wastewater Treatment Plants

- High bandwidth form potable water to hazardous wastewater

- No VOC, no effect on potable water

- Virtually no permeability to water

- Great acid and microbial resistance

- Withstands constant immersion

- Remains flexible and resilient

- Short construction window makes it highly cost-effective

- Less expensive than previous GRP liners

- Potable water reservoirs, sewage treatment plants, primary/secondary containments, chlorination basins, clarifiers, filtration systems, pump stations, aeration tanks, digesters, sludge compartments, etc

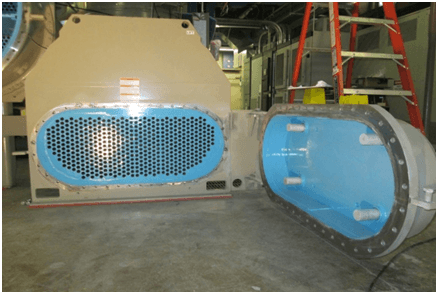

Power Industry

Offers a longer lasting protection against corrosion,

chemical attack and high temperatures

Nuclear, fossil, hydro, wind and alternative generation

Prevents transmission towers and substation structures from weathering

Flooring systems for power plants

Oil, water and chemical storage tanks and containment areas

Tank liners, cooling towers, stack, secondary containment, splash zones, cable ducts, etc.

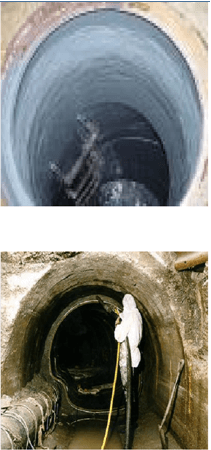

Manhole and Sewer Linings

- Rehabilitation of manholes & sewer systems

- Excellent adhesion to brick, block and concrete

- Resistant to caustic or corrosive chemicals/ gases

- Moisture insensitive

- Maintains tensile strength and flexibility

- Excellent crack-bridging ability

- Protects cavity from sediment

- Provides structural enhancement

- Long-term stability and life

- Fast cure decreases the return-to-service time

- Less expensive than previous GRP liners

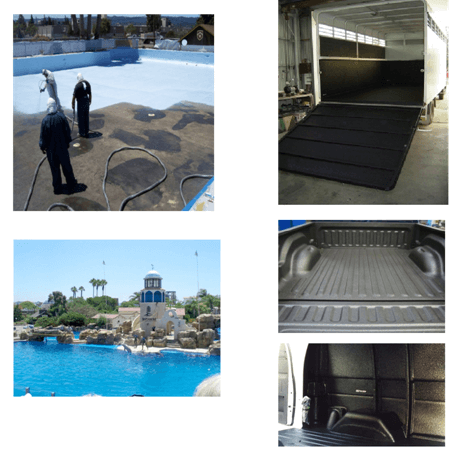

Transportation and Trucks

Bedliners form a durable, permanent, water-tight liner

Abrasion resistance protects from harsh environments against rust and corrosion

Easy to clean

Pick-up trucks, animal transport, refrigerator trucks,dump trucks, cement mixers, rail cars, steel containers, mining trucks etc.

Hotel and Leisure Park Industry

Waterproofing of pool and water body areas as a

sub-layer Ability to form custom shape walls

Waterscapes, molded slides, coating for seats in wet/dry conditions, aquariums, pools, non skid areas, ponds, etc.

Benefits of our systems make them amongst the lowest in term of life cycle cost

| Benefit | Features |

|---|---|

| Resistant to Abrasion | Outperforms many rubber, plastics and metals Strong, impact resistant and exhibit excellent abrasion resistance allowing for the fabrication of products using less substrate material, reducing weight and production costs. Extended service life reduces maintenance and down time costs. |

| Highly Resistant to Impact | More elastic than conventional plastics and epoxies – resists fracturing and de-lamination. Tremendous strength and flexibility allows our products to absorb impact that will fatigue and fracture traditional materials. This makes our material ideal for parts that have to stand up to high impact. |

| Suitable for High flex applications | Under repeated flexing our lining will not crack, peel or warp Linings retains physical strength, elongation properties impact and abrasion resistance regardless of flexing impact or vibration. |

| Flexible at Low Temperature | Linings will maintain flex properties as low as -20 C Our linings are resistant to thermal shock withstanding severe temperature changes without losing their physical properties |

| Stable up to 150C | Suitable for continuous exposure in environments up to 120C. Intermittent exposure as high as 160C. Performance varies depending on substrate |

| Won’t Sweat or Deteriorate in water | Remains stable exposed to continuous immersion at 80C Absorbs almost no water – barely 0.3% to 1.6% by weight (depending on product)- and shows negligible swelling even after prolonged immersion |

| Electrical Properties | SP products are excellent insulators Can be used in protecting joints in power cable and other encapsulating applications where electrical isolation is important |

| Resistant to Oil, Grease and Chemicals | Linings will resist a much wider range of chemicals, oils and fuels than traditional rubbers, epoxies and plastics. |

| Radiation Resistant | Best resistance to gamma ray radiation of all elastomers After exposure, our linings retain virtually all of their original flexibility and toughness |

| Bonds to Wood, Metals and Most Plastics | Bond strengths on wood, metal and plastic substrates usually stronger than the substrate itself Usually several times stronger than a similar rubber-to- substrate bond |

| Noise Reduction Capacity | Ideal for sound-deadening and anti-vibration applications Can substantially reduce noise and vibration because of its flexibility and extreme resilience |

We Provide The Best Service In Industry

We’re here to help you and answer any question you might have. We look forward to hearing from you😀